The 800 mesh sieves with a lid and receiver, free of film, grease, or other water, repellent material, Petri dish, stoppered conical/flat bottom flask. Sieve analysis, Laboratory test sieves.

Reagents:

10-15% AOS or any detergent solution.

{tocify} $title={Table of Contents}

Sieve Analysis Procedure

1. Weigh

accurately about 10 g of the material and transfer it into a 250 ml stoppered

conical flask.

2. Add to it

about 50 ml of AOS solution (approximately 10-15%). Shake well to have effective

dispersion.

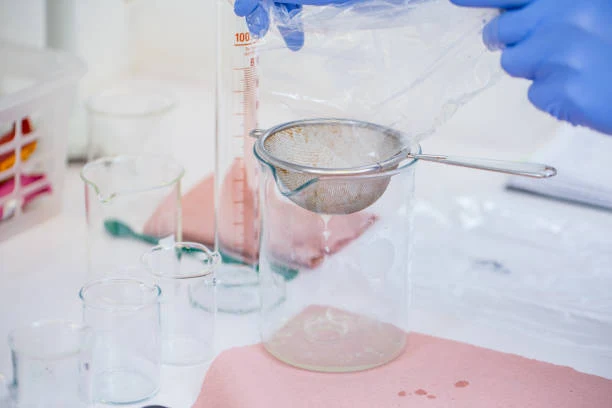

3. Take a

clean dried sieve of 800 mesh. Pour the talc dispersion into the sieve and place

it under a running water tap.

4. Rinse the

conical flask with approximately 50 ml of water and pour the remaining contents

into the sieve.

5. Repeat

the operation to ensure complete transfer of talc from the flask.

6. Rub

gently the dispersion with figures on the sieve for easy passing through the

mesh.

7. Continue

the operation taking care to avoid any spillage, till the entire quantity that

can pass through the sieve is passed off.

8. To have

better and more effective transfer pour 10-15 ml of AOS solution in the sieve

under running water.

9. After

complete washing the sieve along with the retention, if any, is dried at 105°C

for 1 hour. Ensure completion of drying.

10. Transfer

carefully the dried-up retention in a clean and previously tared Petri dish;

weigh the same and calculate the percentage retention on a sieve.

Sieve analysis Calculation:

W1

Residue

on 800 mesh sieves = ------ x 100 % w/w

W

Where,

W1 = weight

of the residue on 800 mesh sieve.

W = weight

of sample taken.

Microscopic examination Procedure

A 5.0 mg sample is placed on a microscope slide and spread evenly over the whole cover glass.

The full test surface is examined qualitatively at low magnification (e.g. x50) for any inhomogeneities or agglomerations, then ten non-overlapping fields of vision are evaluated at x200 magnification along one diameter of the observation surface and the mean value is

Calculated of mesh size.

The mean figures from ten observation surfaces must include no more than five particles greater than 10 μm and none over 100 μm.

Sieve Analysis for Particle Size Distribution

This method applies to the determination of the

particle size distribution of powder raw materials used in the manufacture of

mosquito coils.

Sieve Analysis Principle

This test method determines the percentages of particles in

a sample which are graded into different size ranges. This is achieved by

sieving a prescribed amount of powder through a series of sieves of selected

mesh sizes using a sieve shaker for a prescribed period of time.

Equipment for sieve analysis

1) Clean, dry sieves (free of film, grease or other

contaminants) of agreed mesh sizes (British Standard)

2) Sieve lid and bottom

3) Balance

4) Clean weighing dishes and a beaker

5) Mechanical sieve shaker

6) Brush

Procedure :

A) Sampling

Refer to 'Sampling of Mosquito Coil Powdered Raw Materials'

(Test Method Reference 31488)

B) Sieve analysis Test Procedure

1) Stack the sieves, including the bottom, according to

their ascending mesh sizes (ie smallest aperture at the bottom, largest

aperture at the top)

2) Place a clean beaker on the balance and tare the balance

3) Accurately weigh 100g of sample into the beaker

4) Carefully transfer all of the contents of the beaker into

the top sieve

5) Place the sieve lid on the top sieve, then place the

stack of sieves on the sieve shaker and secure it properly

6) Switch on the sieve shaker and shake the sieves for 20

minutes

7) After stopping the sieve shaker, allow the sieves to stand

for about ten minutes before opening to ensure that all dust settles

8) Transfer the material retained in the first sieve into a

clean, weighed dish, using a brush to ensure that all material is transferred

9) Record the weight of this retained material, W1 (g)

10) Repeat step 8 for all the other sieves, and the bottom

catch dish, recording the weight of material for each particle size fraction

11) The total weight of powder collected in the sieves and

bottom should be very close to 100g. That is, there should be very little loss

during the sieving and transfer process

12) Calculate the percentage of material retained by each

sieve and that passed by the last sieve (the amount collected in the bottom) as

below

13) Suggested sieves to be used for the analysis are (Refer

to specification for actual sieve sizes) :

Sieve No Mesh Size (BS)

A 60

B 100

C 200

D 300

E Passed through 300 (<300)

Calculation of Sieve analysis:

For each Sieve determine the amount retained as below:

Fraction of Sample Retained on Sieve X (%) = W1 x 100/100

Where:

X is each of sieves A, B, C, D and E

W1 is the amount of sample retained on the particular sieve

Result :

The Particle Size Distribution for the sample is determined

as below :

Fraction of Sample greater than 60 mesh = A%

Fraction of Sample greater than 100 mesh = (A + B)%

Fraction of Sample greater than 200 mesh = (A + B + C)%

Fraction of Sample greater than 300 mesh = (A + B + C + D)%

Fraction of Sample smaller than 300 mesh = E%

The total of A, B, C, D, and E should be 100%

Determination of the appearance of a powder by a visual evaluation.

The sample is visually examined against a set of criteria

and against a suitable reference standard to determine its acceptability.

Safety

Observe proper laboratory safety rules, personal protection, and chemical handling procedures at all times.

Read MSDS before handling chemicals and products.

Apparatus

Suitably sized beakersProcedure for the appearance of a powder

1) Read the specifications for the product being tested.

2) Pour the product out into a small beaker.

3) Compare the sample to the description in the

specification. Pay particular attention to:

- colour

- texture

- any foreign matter

- any lumps

4) Compare the sample to the standard reference sample.

Results:

Report the sample as comparable or not comparable to the

reference standard

Hello. What is the AOS solution you keep referring to?

ReplyDelete