There are a few different types of classifiers that are commonly used. The first type is a rotary classifier, which uses a rotating drum to classify materials. The second type is a vibrating classifier, which uses vibrations to help separate the particles. The third type is a gravity classifier, which relies on gravity to help separate the materials.

Classification is defined as the separation of solid particles into fractions based on their terminal settling velocities. Suppose, for example, that the solid particles to be separated are fed in suspension into a tank of a large cross-sectional area.

{tocify} $title={Table of Contents}

Types of Classifiers in Mineral Processing

There are many different types of classifiers in mineral processing, each with its own unique characteristics and applications. Here is a brief overview of some of the most common types:

Gravity Settling Tank/Gravity classifier

It is the simplest type of classifier. It consists of a large tank with provisions for a suitable inlet and outlet.

A slurry feed enters the tank through an inlet connection. As soon as slurry feed enters the tank, its linear velocity decreases as a result of the enlargement of the cross-sectional area. Solid particles start to settle under the bottom of the tank near the inlet, while the slower-settling particles will be carried farther into the tank before they reach the bottom of the tank. The very fine particles are carried away in the liquid overflow from the tank.

Vertical baffles placed at various distances from the inlet within the tank allow for the collection of several fractions according to the terminal falling velocities. Because of the occurrence of considerable overlapping of size, no sharp separation is possible with this classifier.

Gravity Classifier uses

Gravity classifiers are used in a variety of industries to separate materials based on their specific gravity. Specific gravity is the ratio of the density of a substance to the density of water.

Gravity classifiers are typically used to remove light, worthless materials, such as clay and dust, from a product. By doing so, manufacturers can increase the overall purity of their products. Additionally, gravity classifiers can be used to separate products that are of different densities.

One common use for a gravity classifier is to remove fine coal from a product stream. By removing the fine coal, power plants can reduce their emissions.

Gravity classifiers are also used in the food industry. For example, they can be used to remove shells from nuts. Additionally, they can be used to remove foreign objects from food products.

Cone Classifier/Cone classifier working

A cone Classifier is simply a cone a conical vessel, installed point down, with a discharge launder around the top. The feed is introduced in the form of a suspension through a fed inlet provided at the top. The coarse fraction collects at the point of the cone and is withdrawn periodically or continuously.

The fine fraction along with the remaining portion of the liquid is removed from the launder as an overflow. The separation achieved with this unit is only an approximate one. Cone classifiers, though one of the oldest types are still used for relatively crude work because of the low cost of installation. They are used in ore-dressing plants.

Double Cone Classifier Working Principle

This classifier uses hydraulic water for classification (a stream of additional water supplied to a classifier is called hydraulic water)

The double cone Classifier is shown in the picture. It consists of a conical vessel inside of which is a second hollow cone. The inner cone is slightly larger in angle, arranged apex downward, and is movable in a vertical direction.

The to-be-separated is fed in the form of a suspension to the centre of the inner cone. It flows downward through the inner cone and out at a baffle at the bottom of the inner cone and a rising stream of water is fed near the outlet for the coarse material.

The solids form the inner cone and then flow through an annulus space between the two cones. Classification action occurs in the annular space, the small particles are carried away in the overflow while the occurs in large Particles settle against the hydraulic water to the bottom and are removed periodically.

Rake Classifier Working Principle (Mechanical Classifiers)

The rake/mechanical classifier such as the door classifier consists of a rectangular tank with a sloping/inclined bottom. The tank is provided with movable rakes. The feed in the form of a suspension or slurry is introduced continuously near the middle of the tank. The lower end of the overflow from which the fines that are not settled leave with the overflow from which the fines that are not settled leave with the overflow liquid.

The heavy material sink to the bottom of the tank. The rakes scrap the settled solids upward along the bottom of the tank toward the top of the tank for discharge from a sand discharge chute. The reciprocating rakes keep the slurry in continuous agitation. The time of the raking stroke is so adjusted that fines do not have time to settle and so remain near the surface of the slurry while the heavy particles have time to settle.

Spiral Classifier Working Principle

Another mechanical classifier is the spiral classifier. The spiral classifier such as the Akins classifier consists of a semi-cylindrical trough inclined horizontally. The trough is provided with a slow-rotating spiral conveyor and a liquid overflow at the lower end. The spiral conveyor moves the solids which settle to the bottom upward toward the top of the trough.

The slurry is fed continuously near the middle of the trough. The slurry feed rate is so adjusted that fine particles do not have time to settle and are carried out with the overflow liquid. The heavy particles have time to settle, they settle to the bottom of the trough and the spiral conveyor moves the settled solids upward along the floor of the trough toward the top of the trough/the sand product discharge chute.

Note: Rake and spiral classifiers are used for closed-circuit grinding.

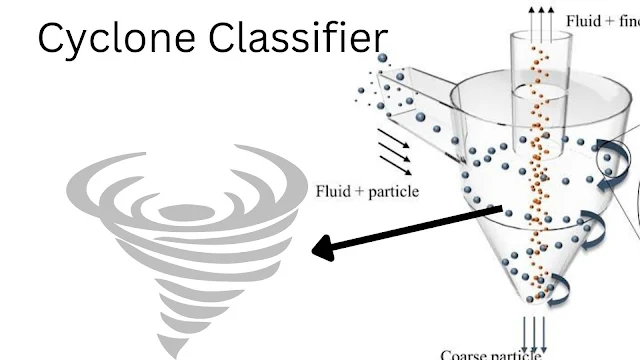

Cyclones Separators Working Principale

A cyclone separator is essentially a settling chamber in which the gravitational separating force is replaced by a much stronger centrifugal separating force.

Cyclones separators are used for the separation of solids from fluids. They offer one of the least expensive means of dust collection from both an operating and an investment viewpoint. They utilize centrifugal force to effect the separation which depends on particle size and on particle density. Thus cyclones are used to effect a separation based on particle size particle density or both.

In this separator, used for the separation of dust particles or mist from gases, the dust-laden gas is introduced tangentially into a cylindrical vessel at a high velocity (about 30 m/s). Centrifugal force throws the solid particles out against the wall of the vessel and they drop into a conical section of the cyclone and are removed from the bottom opening. The clean gas is taken out through a central outlet at the top.

Hydrocyclone Separator Working Principle

Hydrocyclone separators may also be used to affect the classification of solid particles suspended in a liquid. In such cases, the commonly used liquid is water.

A liquid cyclone or hydrocyclone has a top cylindrical section and a lower conical section terminating in an apex opening. The top vertical section is covered by a flat plate and is provided with a tangential inlet at the top. The cover has a downward extending pipe to cut the vortex and remove the overflow product since the viscosity of water is much higher than that of a gas, the fluid resistance encountered in this cyclone is greater than that in the cyclone used for dust collection.

Therefore the diameter of this cyclone must be smaller to get a corresponding greater centrifugal force. Consequently, the diameter of the cylindrical section is less than 375 mm and the cone angle is 16° to 20°. Inlet pressures of the feed to the cyclone lie between 5 to 120 psi.

The slurry feed is pumped into the cylindrical section tangentially. Coarse or heavy solids thrown out against the walls, travel down the sides of the cone section and are discharged in a partially dewatered form at the apex, while the smaller or lighter solids along with the remaining portion of water are removed from the downward extending pipe at the top. Hydrocyclone finds application in degritting operations production, classifying pigments, and ore-dressing practice.

Hydrocyclone uses

A hydrocyclone is a device that uses centrifugal force to separate solid particles from a liquid or to separate liquid particles from each other. Hydrocyclones are used in a variety of industries, including oil and gas, mining, and manufacturing.

Also Read: Magnetic Materials Separation Methods or Techniques

Take these Notes is, Orginal Sources: Unit Operations-II, KA Gavhane