The uses, advantages, working, and construction of reciprocating pumps which are as follows.

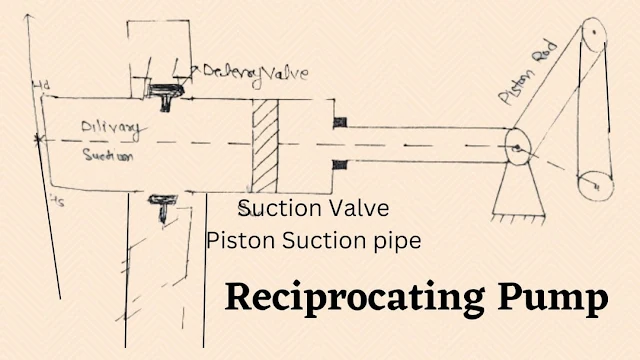

Construction of Reciprocating pump

The main parts of the Reciprocating Pump are the cylinder, piston valve, etc.

Cylinder: It is generally made of cast iron and attached to a suitable base as required. The piston moves back and forth inside the cylinder, at the same time there are valves on the cylinder for entry and exit.

Piston: It is generally made of cast iron. The piston moves back inside the cylinder. The piston is held together with the help of piston walls.

Valve: The dis valve is widespread in almost all types of reciprocating pumps. This valve is a disc of rubber that has a hole at its center and with the help of the hole it returns to its seat by air pressure.

Reciprocating Pump Working Principle

The reciprocating pump works at a simple and low speed, so it is often coupled with an electric motor with the help of a belt, etc.

One side section (valve, pipe) and delivery (valve, pipe) are engaged in the cylinder. When the piston moves to one side, vacuum pressure is generated in the cylinder.

Due to this, the suction valve opens, the evaporation of water on the pressure in the suction pipe becomes dependent and now the piston presses the liquid, due to which the suction pipe closes, and the delivery valve opens, as the piston presses the liquid, the liquid delivery pipe gets in and it is pumped to the designated place.

Reciprocating Pump Uses and Advantages

Uses for Operation

(i) Reciprocating pump is used for low capacity and high pressure.

(ii) It is also used in well drilling operations.

(iii) It is used as a hand pump or oil pump in houses etc.

Use Reciprocating Pumps in industry

It also used Reciprocating pumps in different types of industries like chemical processing, Food industry, wastewater treatment, soap manufacturing, paper and pulp manufacturing, and mining.

Advantages of Reciprocating Pump

(i) A reciprocating pump provides a constant, unchanging flow rate whereas a centrifugal pump's flow rate can fluctuate during operation.

(ii) Use for Reciprocating pumps are ideal for high-pressure, low-flow.

(iii) Reciprocating pumps generally operate at a higher efficiency than the other pumps, with efficiency levels of 90% or more.

(iv) While reciprocating pumps rarely require priming, Centrifugal pumps always require priming.

(v) Reciprocating pumps generate a greater amount of pressure per operation than centrifugal pumps.

For example, Reciprocating pumps used in water jet cutting can generate pressures over 10,000 psi.