Apart from the mechanical properties of materials stated so far, another important property is corrosion resistance. All metals are thermodynamically unstable and tend to react with their environment to produce compounds such as oxides or carbonates.

This reaction involves the movement of electrons and is called an electrochemical reaction.

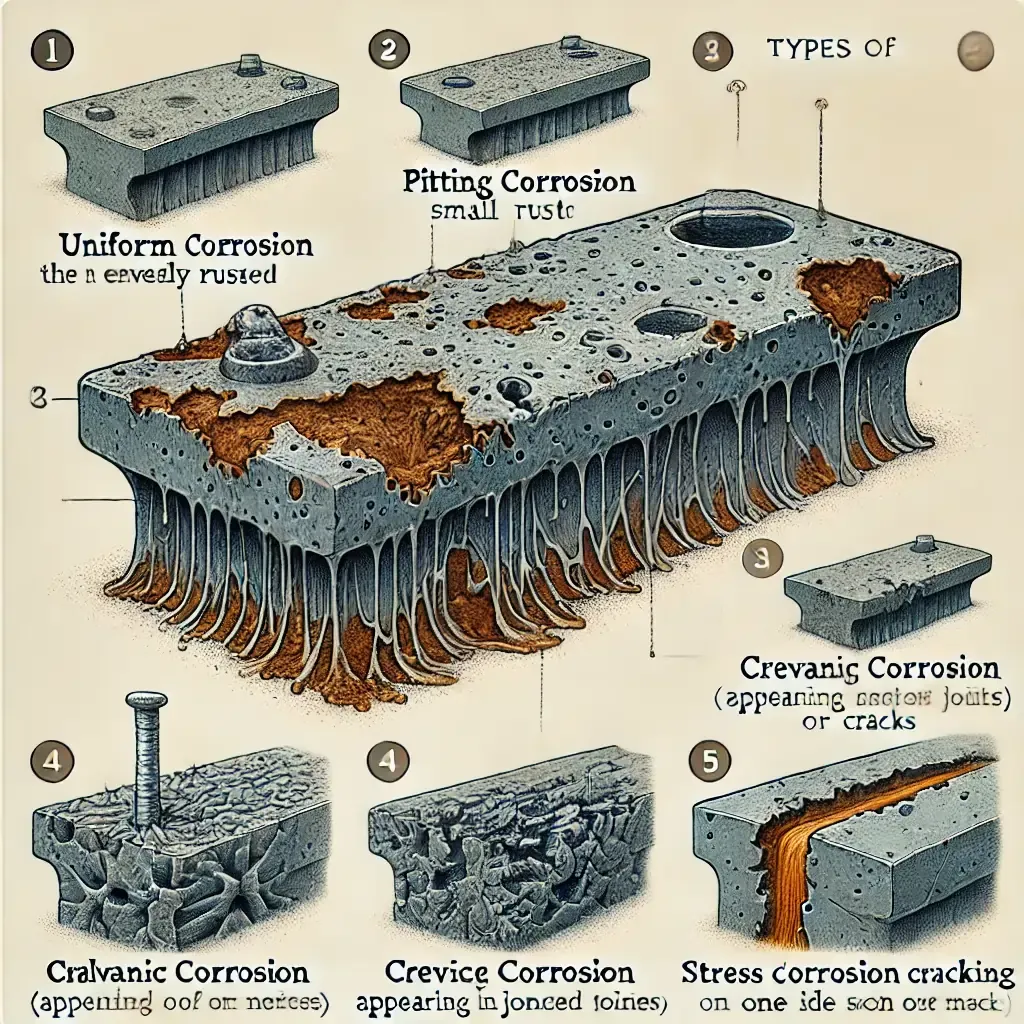

Types of Corrosions

Uniform Corrosion

This is the

most common form of corrosion, characterized by the chemical or electrochemical reaction that proceeds evenly and uniformly over the entire

exposed area. It is indicated by the general wasting of the surface. The corrosive

product may either form a protective layer on the metal or, in the case of a direct chemical attack, the corroded material will dissolve in the corrosive environment.

This type of corrosion can be prevented or reduced by (i) Coating, (ii)

Inhibitors, or (iii) Cathodic protection.

Galvanic corrosion

This occurs when two dissimilar metals are placed in contact. The less resistant metal becomes anodic, and the more resistant metal becomes cathodic. Usually, the corrosion of cathodic metal is nil or very little in this type of couple. For example, in heat exchangers with copper tubes and cast iron or steel tube sheets, if galvanic corrosion occurs, it accelerates the attack on heavy tube sheets instead of thin copper tubes.

- Select the combination of metals as close together as possible in the galvanic series.

- Avoid the unfavourable area effect of a small anode and a large cathode.

- Insulate dissimilar metals whenever possible.

- Apply coating with caution.

- Add inhibitors, if possible, to decrease the aggressiveness of the environment.

- Avoid threaded joints for materials far apart in the galvanic series.

- Design a system for ease of replacement of anodic material. Also, one can have a thicker anode.

- Provide for cathodic protection.

Crevice

Corrosion

This is

intense localized corrosion that occurs within crevices and other shielded

areas on metal surfaces exposed to corrosives. This type of attack is usually

associated with small volumes of stagnant solution caused by holes, gasket

surfaces, lap joints, surface deposits and crevices under bolt and rivet heads.

Stainless steels are particularly susceptible to revice attack.

Pitting Corrosion

This occurs

between surfaces that are in close contact. It is extremely localized and occurs

due to the presence of impurities, rough spots and scratches. Pitting seldom occurs

with extreme suddenness. It occurs due to stagnant conditions, which implies

that in equipment where a conditions flow of liquid is present, it often exhibits

reduced pitting. Adding inhibitors to metals helps reduce pitting.

Intergranular corrosion

This consists

of a localized attack or an intercrystallite cracking along the grain

boundaries of the metal. It is caused by impurities at the grain boundaries, enrichment of one of the alloying elements or a depletion of one of these

elements in the grain-boundary areas.

Selective leaching

In this

type of corrosion, one element of a metal or alloy is singled out for attack. The

common types are dezincification, dealuminations and graphite erosion. For

example, if copper zinc alloys containing less than 85% copper are exposed to

wet conditions, this type of corrosion occurs for redeposited copper that has little

mechanical strength.

Stress corrosion

This

corrosion is the result of internal or external stresses and a corrosive

environment. It manifests itself in the form of cracks, and it is therefore often

known as stress corrosion cracking. Many metals and some plastics suffer from

this effect. With plastics, it is called environmental cracking. The important

variables affecting stress corrosion cracking are temperature, solution

composition, metal composition structure and stress.

Fatigue Corrosion

As in the

case of stress corrosion, where static stresses are linked up corrosion in this

type of corrosion cyclic load combine with corrosion to cause corrosion

fatigue. Usually, fatigue failures occur at stress levels belowthe yield point and

after many cyclic applications of this stress.

Erosion Corrosion

This is caused

by the combination of corrosive fluid and mechanical wear resulting from the impingement

of liquid or abrasion of solid particles. This effect is mainly dependent on

the liquid velocity and on account of the contained air solids or any factors

that affect the rate of formation of protective films. This process removes layers

from the surface of the metal as dissolved ions form from the metal surface.

Gravitation Corrosion

This is a

special form of corrosion that occurs due to the repeated collapse of vapour

bubbles on a metal surface. This causes mild physical damage to the protective films and severe deformation and fracture of the surface. Cavitation occurs in equipment

where a high-velocity liquid flows and pressure changes are encountered, such as

pump impellers, resulting in vapour bubbles.

Fretting Corrosion

This occurs

at the contact areas between materials under load subjected to vibration and

slip. It appears as pits or grooves in the metal surrounded by corrosion

products. Fretting is also called friction oxidation or wear oxidation.

This type

of corrosion can be minimized by lubricating contact areas or by increasing

the hardness of one or both of the contacting materials.

Hydrogen Damage

This refers to the mechanical damage of metal caused by the presence of or by the interaction with hydrogen. This can be in the form of hydrogen embrittlement decarburization or hydrogen attack.